Services

Take advantage of our experience from various industrial operations to increase the reliability, efficiency or even the life of your equipment.

Diagnosis of thermal insulation. Focus, design, delivery and installation directly at the customer’s site.

Implementation, operation and maintenance of technological equipment and units.

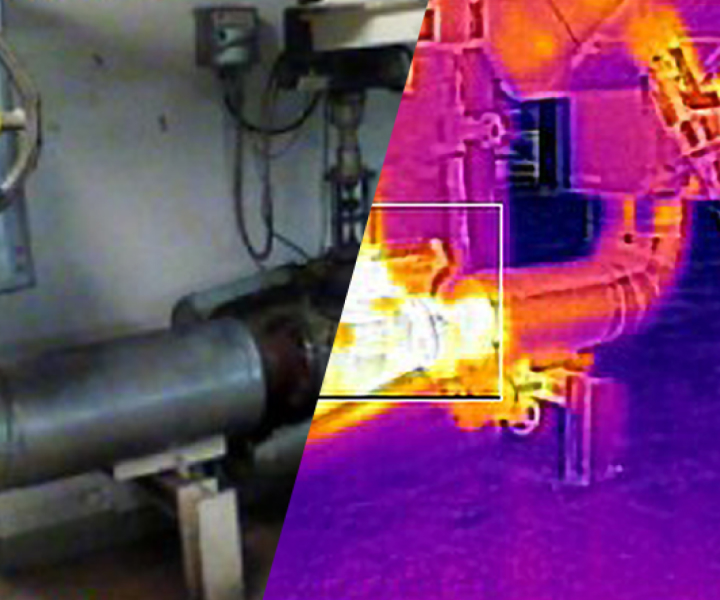

Optimisation of steam-condensate systems

Along with rising energy costs, the need for maintenance and optimization of steam-condensate systems increases. We offer you a comprehensive concept of technical solutions in the field of steam condensate systems, which will reduce your operating costs and at the same time increase the reliability of the system.

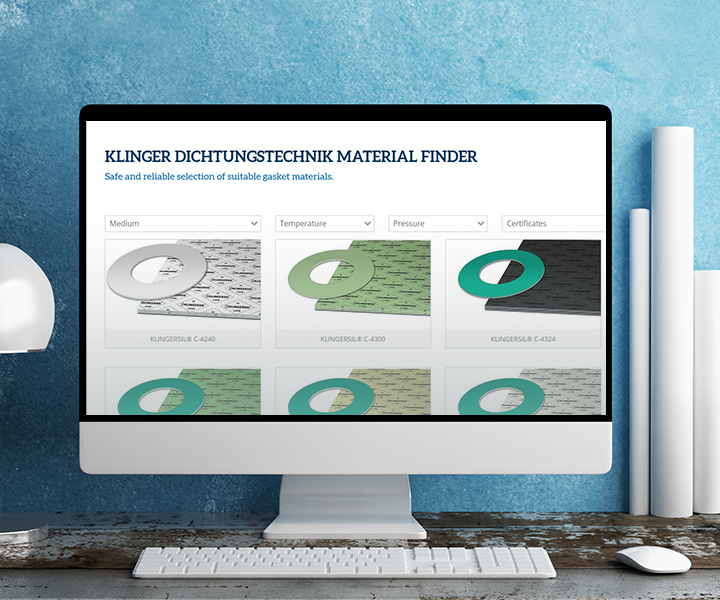

Consultation in the selection of gaskets, calculation of tightening torques in KLINGER Expert

The Klinger® Expert program assists users in choosing the appropriate non-metallic sealing material from the Klinger porfolio. The program works on the basis of European industrial standards and norms.

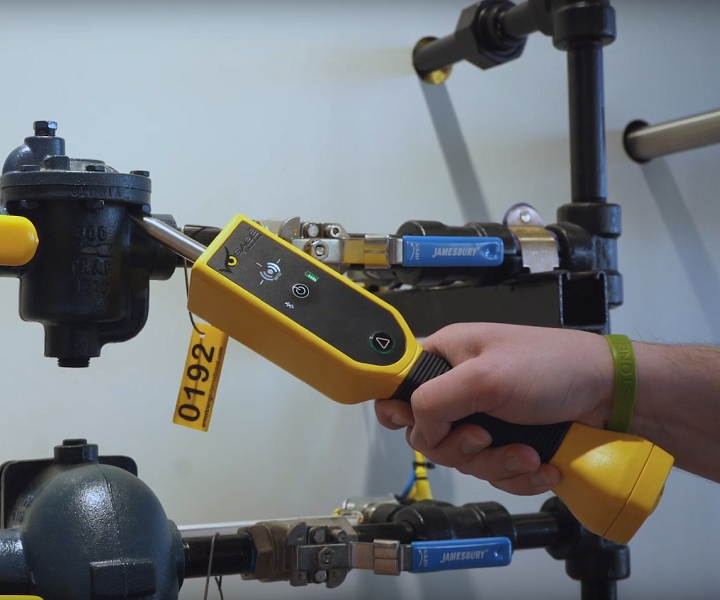

Steam trap survey

Steam traps are an integral part of steam distribution systems. Traps may be installed on steam mains, tracing systems or at various types of exchangers, their correct functionality is essential for the effective function of the entire steam/condensate system.

Pre-Audit of steam-condensate systems

This is a preliminary assessment, or personal inspection, of your system / equipment, which will allow us to gather important information about the infrastructure of your steam-condensate. We focus primarily on identifying locations suitable for increasing operational efficiency, reducing energy consumption, but also improving safety. Armstrong's steam specialists will propose solutions and adjustments in the final report that can be implemented in the short and long term.

Selection of KLINGER seals according to operating substance and parameters

Safe and reliable selection of KLINGER sealing material according to the working substance or its concentration, operating temperature, pressure or required certificate.